ASSIGNMENT 8

Failure Mode and

Effects Analysis (FMEA)

Failure

mode and effects analysis (FMEA) is a team – based methodology for identifying

potential problems with the new or existing designs. It is the first step of a

system reliability study. FMEA is the core task in reliability engineering,

safety engineering, and quality engineering. FMEA involves reviewing as many

components, assemblies, and subsystem as possible to identify failure modes,

and their causes and effects. In order to determine the components of the

process that are most in need of change, FMEA includes the following steps:

1. Steps

in the process.

2. Failure

modes (What could go wrong?)

3. Failure

causes (Why would the failure happen?)

4. Failure

effects (What would be the consequences of each failure?)

Three factors that are considered in developing a FMEA:

1. The

severity of the failure.

2. The

probability of occurrence of failure.

3. The

likelihood of detecting the failure in either design or manufacturing, before

the product is used by the customer.

Different types of FMEA analysis:

1. Functional,

2. Design,

and

3. Process

FMEA.

Major benefits derived from a properly implemented FMEA are as follows:

1. It

provides documentation in selecting design with high probability of successful

operation and safety.

2. A

uniform documentation method of assessing potential failure mechanism, failure

modes and their impact on system operation, resulting in a list of failure

modes ranked according to seriousness of their system impact and likelihood of

occurrence.

3. Early

identification of single failure points (SFPS) and system interface problems

which may be critical to mission success and/or safety.

4. An

effective method for evaluating the effect of proposed changes t the design

and/or operational procedures on mission success and safety.

5. A

basis for in – flight troubleshooting procedures and for locating performance

monitoring and fault – detection devices.

6. Criteria

for early planning of tests.

Example of FMEA

analysis for car tire:

Keywords:

SEV – severity

OCC – occurrence

DET – Detection

RPN – Risk Priority

Number

Criteria for FMEA

Analysis

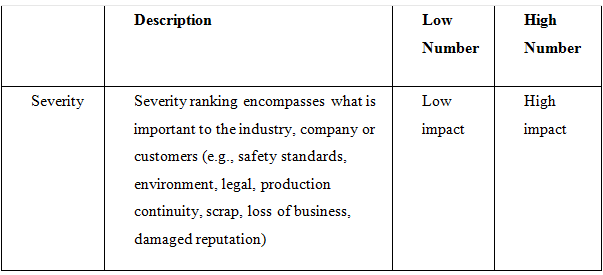

FMEA is analyzed based on three criteria:

1. Severity

effect on customer.

2. Occurrence

of failure.

3. Easy

to detect.

It is then ranked from 1 (low) to 10 (high) for each criterion.

Table 1: Severity,

Occurrence and Detection Ratings

Formula for RPN is:

RPN = severity x occurrence x detection

No comments:

Post a Comment